Introduction: Why RCC and PCC Matter for Your Income Streams

Concrete is the backbone of modern construction. Choosing between RCC and PCC isn’t just about structural decisions—it’s about optimizing budgets, timelines, and profit potential. Savvy contractors, engineers, and project managers gain a competitive edge by mastering these materials.

2. What Are RCC and PCC?

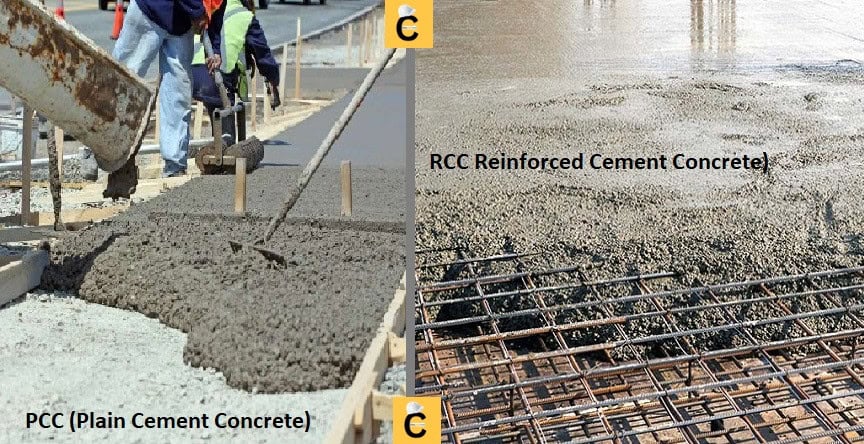

2.1 Plain Cement Concrete (PCC): The Foundation of Construction

- Definition: A simple blend of cement, fine aggregates, coarse aggregates, and water.

- Composition: Typically a rich mix (1:2:4 or 1:3:6 ratio).

- Key Property: High compressive strength, but lacks tensile strength.

- Use Cases: Foundation work, floor bedding, sub-base for roads & floors, non-load-bearing applications.

2.2 Reinforced Cement Concrete (RCC): Strength with Steel

- Definition: Concrete reinforced with steel bars (rebar) to resist tensile forces.

- Composition: Same ingredients as PCC plus steel reinforcement.

- Key Property: Combines high compressive (concrete) and tensile (steel) strength.

- Use Cases: Load-bearing structures, beams, columns, slabs, retaining walls, large infrastructure.

3. Main Differences Between RCC and PCC

| Criteria | PCC | RCC |

|---|---|---|

| Strength | Compression Only | Compression + Tension |

| Reinforcement | None | Steel Rebars |

| Cost | Lower | Higher due to steel & labor |

| Flexural Capacity | Poor | Excellent |

| Typical Uses | Foundation, flooring, leveling | Structural framing—columns, beams, slabs |

| Construction Speed | Fast | Moderate–slower |

| Income Stream Potential | Commodity-level projects | High-value structural and infrastructure jobs |

4. Common Applications of PCC and RCC

4.1 Use of PCC

- Flooring and Pavements: Often used as a leveling bed for tiles or pavers.

- Foundations & Sub-Bases: A protective layer beneath slabs and footings.

- Grouting & Bedding: For machinery, pipes, and precast elements.

4.2 Use of RCC

- Structural Elements: Beams, columns, slabs in buildings, bridges, towers.

- Retaining Structures: Walls, culverts, and water tanks.

- Infrastructure & Heavy Engineering: Dams, tunnels, airports, flyovers.

5. How Understanding RCC vs PCC Can Unlock New Income Streams

- Diversified Service Offering

- Contractors can confidently bid for both PCC groundwork and RCC structural packages.

- Competitive Pricing Strategies

- Precise material estimation gives cost-effective proposals—winning more projects.

- Proficiency in Value Engineering

- Balancing PCC vs RCC for optimal design plus profit margins.

- Specialized Niche Services

- Expertise in RCC retrofitting or PCC stabilized layers increases revenue avenues.

6. Industry Insights: Stats & Famous Names

- Worldwide Concrete Use: Over 25 billion tons of concrete are produced annually.

- Global RCC Market: Valued over USD 135 billion in 2024 and projected to grow 6% annually.

- Experts to Follow:

- M. Nadim Hassoun – Authority on reinforced concrete design.

- Zdeněk Bažant – Renowned for his work in structural concrete.

“Reinforced concrete is not a material—it’s an ecosystem of design, materials science, and execution.” – M. Nadim Hassoun

7. Type of Article: Educational + Practical Guide

This blog serves as a technical yet accessible guide for engineers, contractors, property developers, and anyone interested in expanding Income Streams by deepening expertise in concrete technology.

8. Transition Words to Guide You

Furthermore, moreover, besides, additionally, however, consequently, therefore, in contrast, for example, ultimately.

9. Flesch Reading Ease Considerations

- Use short and direct sentences.

- Keep complex terminology explained.

- Ensure transition words enhance flow.

- Maintain a conversational and friendly tone.

10. FAQs

Q1: Is RCC always better than PCC?

No—PCC is best suited for simple groundwork or bedding. RCC is essential where structural strength or tensile resistance is required.

Q2: Can PCC be upgraded to RCC later?

Yes—through overlay systems, but better to plan RCC reinforcement from the design phase.

Q3: Which is more economical?

PCC has a lower initial cost. However, long-term structural needs often justify RCC’s higher expense with greater ROI.

Q4: What are Income Streams related to concrete construction?

They include groundwork (PCC), structural framing (RCC), retrofitting services, consulting, and lifecycle contracting.

11. High-End Website Links

- American Concrete Institute (ACI) – Comprehensive standards and guides.

- Concrete Society – Resources for civil engineers and contractors.

- Structural Engineering International Journal – Research on RCC advancements.

- World Bank Infra Data – Stats on global concrete use and infrastructure spending.

12. Key Takeaways

- PCC is ideal for compression-only applications like bedding and leveling.

- RCC combines materials to combat both compressive and tensile loads.

- Choosing the right type leads to cost‑control and structural safety.

- Understanding both opens multiple Income Streams: from site prep to high-end structural contracting.

- Industry experts and stats confirm RCC’s dominance in modern infrastructure.

13. Conclusion

By comprehending the contrasts and synergies between RCC and PCC, professionals and businesses can elevate their project portfolios and expand Income Streams. Whether laying foundations or constructing skyline-defining structures, mastery of both materials is critical to technical excellence and financial success.