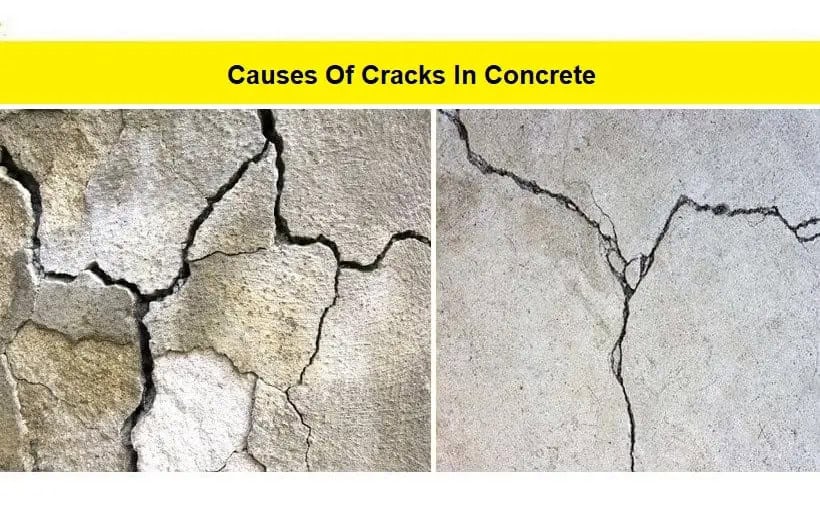

Architects and engineers worldwide know that cracks in concrete structures are common—and often preventable. In architectural design and construction, understanding why concrete cracks occur ensures long-lasting, durable buildings. Consequently, this article explores the architectural causes, effective prevention, reliable repair methods, expert insights, statistics, and FAQs to help professionals and homeowners alike.

1. Structural Causes of Cracks

1.1 Shrinkage (Plastic & Drying)

As concrete cures, it shrinks due to moisture evaporation. This shrinkage creates plastic cracks early on and drying shrinkage cracks later. According to ProAll Inc., “shrinkage is one of the most common causes of cracks”. Notably, high water‑cement ratios exacerbate this

1.2 Settlement & Subgrade Movement

Uneven foundation movement—often caused by poor soil or compaction—leads to settlement cracks. Atlanta Basement Systems explains how poorly compacted soil or water drainage issues cause settlement leading to structural “sinking, broken slabs, and diagonal cracks” Atlanta Basement Systems.

1.3 Thermal Effects & Freeze–Thaw Cycles

Concrete expands and contracts with temperature changes. Without joints or insulation, this can create thermal cracks. Freeze–thaw cycles: “When water freezes, volume increases by ~9%… causing micro‑cracks” In cold climates, air‑entrained concrete is essential

1.4 Chemical Degradation & Corrosion

Chemical interactions—carbonation, sulfation, alkali-silica (ASR), and chloride attack—deteriorate cement paste. Steel rebar corrosion causes spalling: expanding rust cracks and breaks concrete. Wikipedia states these are “most destructive” and “internal mechanical stress–inducing”

1.5 Overloading & Mechanical Stress

Concrete is strong in compression but weak in tension. Overloading—like heavy vehicles—causes structural cracks. Valcourt notes: “Exceeding weight capacity of concrete can cause cracks” Similarly, crocodile cracking from fatigue stress on pavements arises from repetitive loads

1.6 Improper Mix Design & Curing

A high water‑cement ratio weakens concrete, increasing shrinkage. Improper curing—hot sun, wind, improper moisture—leads to surface cracks. Port Aggregates warns: “Skipping or rushing curing… compromises the longevity”

2. Architectural Prevention Strategies

2.1 Optimal Mix Design

- Use low water‑cement ratio and high‑quality aggregates

- Add shrinkage‑reducing admixtures.

- Incorporate air‑entrainment for climates prone to freeze–thaw

2.2 Foundation & Subgrade Preparation

- Perform soil compaction and geotechnical tests.

- Use structural reinforcements and improve drainage around foundations

2.3 Proper Joint Placement

- Install control joints 30× slab thickness apart

- Include expansion joints in architectural design to accommodate thermal movement

2.4 Quality Curing Practices

- Maintain moisture using water spray, plastic sheeting, or burlap for at least 7 days

- In extreme climates, use insulated blankets (cold weather) or additives/ice (hot)

2.5 Reinforcement & Steel Protection

- Ensure correct rebar placement and adequate concrete cover

- Use corrosion-resistant coatings or stainless steel rebar

2.6 Waterproofing & Chemical Barriers

- Apply sealants or membranes to prevent water ingress

- Use sulfate-resistant cement where high sulfates are present

- Avoid deicing salts to prevent chloride-induced corrosion

3. Repair Techniques

3.1 Surface / Non-Structural Cracks

- Epoxy injections for structural cracks. GSA recommends epoxy resin for both active & dormant cracks

- Patching compounds for hairline cracks.

- Sealants for control joints and expansion joints

3.2 Spalling & Corrosion Damage

- Remove deteriorated concrete, treat and coat rebar, re‑pour with repair mortar. Valcourt details this method

3.3 Settlement / Subgrade Failure

- Under-slab injection (e.g., PolyLevel®) lifts slabs and fills voids

3.4 Freeze–Thaw Damage

- Seal and use air‑entrained mixtures.

- Apply waterproof coatings after repairs

3.5 Self-Healing Concrete (Advanced)

- Employ microbial or polymer fiber technology. Research shows self-healing concrete can recover up to 90 % of strength

4. Expert Quotes & Notable Names

- Dr. W. S. Oehne, from “Effect of frost on concrete,” highlights: “micro‑cracks from freeze–thaw cycles severely reduce early strength”

- Scherer & van Aarle emphasize air‑entrainment: “tiny air-filled micro‑cavities… accommodate ice expansion”

- Valcourt Group reminds: “cracks and spalling… signs of deterioration… moisture and corrosion accelerate damage”

5. Statistics Snapshot

- Concrete is up to 10× stronger in compression than in tension

- 92 % accuracy in crack detection from image-based AI systems

- Self-healing concrete restores up to 90 % durability after three cycles

- Water freezes and expands by 9 % in pores, triggering cracks

- Air entrainment raises freeze–thaw resistance in concrete

6. Key Takeaways

- Architectural foresight ensures long-lasting structures: control shrinkage, joints, and rebar protection.

- Curing is essential—don’t rush it.

- Waterproofing and proper mix design combat both physical and chemical damage.

- Early repairs prevent major issues.

- Innovations like self-healing offer eco-friendly resilience.

7. FAQs

Q1: Are all concrete cracks structurally dangerous?

A: No. Hairline & plastic shrinkage cracks are usually cosmetic. However, deep cracks (>0.3 mm), spalling, or those exposing rebar require professional assessment Port

Q2: How long should I cure concrete?

A: Typically 7 days for normal applications; longer (14 days) may be required in dry or hot climates

Q3: Can old concrete cracks still be fixed?

A: Yes. Epoxy injections, sealants, or patching compounds can effectively repair old cracks, provided the root cause is addressed.

Q4: Is self-healing concrete market-ready?

A: It’s emerging. Fungal- and polymer-based self-healing show promise in labs, recovering up to 90 % strength Commercial use is growing among sustainable architectural projects.

8. Further Reading

- [GSA: Types of Cracks & Solutions]

- [ProAll: Prevention & Repair]

- [Valcourt: Freeze–Thaw & Spalling]

- [Wikipedia: Concrete Degradation Processes]

🔚 Conclusion

Architectural excellence depends on anticipating—and controlling—crack issues in concrete. With proper design, mix, curing, joints, drainage, and regular maintenance, most cracks are preventable. Meanwhile, evolving technologies like self-healing concrete are paving the way for stronger, more sustainable structures. Integrate these best practices and your architectural projects will stand the test of time—and climate.